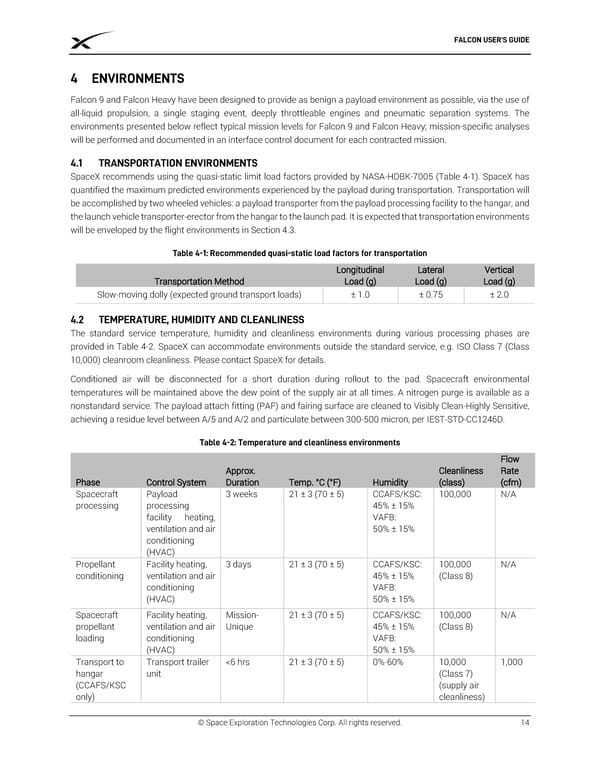

FALCON USER’S GUIDE 4 ENVIRONMENTS Falcon 9 and Falcon Heavy have been designed to provide as benign a payload environment as possible, via the use of all-liquid propulsion, a single staging event, deeply throttleable engines and pneumatic separation systems. The environments presented below reflect typical mission levels for Falcon 9 and Falcon Heavy; mission-specific analyses will be performed and documented in an interface control document for each contracted mission. TRANSPORTATION ENVIRONMENTS SpaceX recommends using the quasi-static limit load factors provided by NASA-HDBK-7005 (Table 4-1). SpaceX has quantified the maximum predicted environments experienced by the payload during transportation. Transportation will be accomplished by two wheeled vehicles: a payload transporter from the payload processing facility to the hangar, and the launch vehicle transporter-erector from the hangar to the launch pad. It is expected that transportation environments will be enveloped by the flight environments in Section 4.3. Table 4-1: Recommended quasi-static load factors for transportation Longitudinal Lateral Vertical Transportation Method Load (g) Load (g) Load (g) Slow-moving dolly (expected ground transport loads) ± 1.0 ± 0.75 ± 2.0 TEMPERATURE, HUMIDITY AND CLEANLINESS The standard service temperature, humidity and cleanliness environments during various processing phases are provided in Table 4-2. SpaceX can accommodate environments outside the standard service, e.g. ISO Class 7 (Class 10,000) cleanroom cleanliness. Please contact SpaceX for details. Conditioned air will be disconnected for a short duration during rollout to the pad. Spacecraft environmental temperatures will be maintained above the dew point of the supply air at all times. A nitrogen purge is available as a nonstandard service. The payload attach fitting (PAF) and fairing surface are cleaned to Visibly Clean-Highly Sensitive, achieving a residue level between A/5 and A/2 and particulate between 300-500 micron, per IEST-STD-CC1246D. Table 4-2: Temperature and cleanliness environments Flow Approx. Cleanliness Rate Phase Control System Duration Temp. °C (°F) Humidity (class) (cfm) Spacecraft Payload 3 weeks 21 ± 3 (70 ± 5) CCAFS/KSC: 100,000 N/A processing processing 45% ± 15% facility heating, VAFB: ventilation and air 50% ± 15% conditioning (HVAC) Propellant Facility heating, 3 days 21 ± 3 (70 ± 5) CCAFS/KSC: 100,000 N/A conditioning ventilation and air 45% ± 15% (Class 8) conditioning VAFB: (HVAC) 50% ± 15% Spacecraft Facility heating, Mission- 21 ± 3 (70 ± 5) CCAFS/KSC: 100,000 N/A propellant ventilation and air Unique 45% ± 15% (Class 8) loading conditioning VAFB: (HVAC) 50% ± 15% Transport to Transport trailer <6 hrs 21 ± 3 (70 ± 5) 0%-60% 10,000 1,000 hangar unit (Class 7) (CCAFS/KSC (supply air only) cleanliness) © Space Exploration Technologies Corp. All rights reserved. 14

SPACEX FALCON USER’S GUIDE Page 17 Page 19

SPACEX FALCON USER’S GUIDE Page 17 Page 19